Where do linear rails commonly use for?

The linear rails have twin tracks that have rollers or supporting balls. It is known to be the backbone of industrial applications. As it gives low friction and durability to any weight. It is available in different sizes and quality as it needs to produce a good performance.

There are different reasons why linear rails are often used. They also have other types of rails that can sustain travel accuracy and load capacity. There is an instance that there is a round shaft that can manage to do liftoff and downward loads. But when they use linear rails they can use both and load them easily. Rather than using crossed roller rails for traveling it is sometimes limited to a meter or less. While the linear rails can manage long travel distances which is a good thing. But when you compare the standard bearing guides the linear rails are durable and have strong characteristics.

guias lineales are a great help as they can be perfect for traveling. Good thing that there is exact machining on both sides of the rail that can act as surfaces. The combination can give a good linear guide which is advisable for applications. It needs a long life, high accuracy, and stability.

The single rail

The linear rails can support the rollers on every side of the rail. It can handle the loads even though it uses a single rail. And because of this quality, it can save up space or avoid any issues with misalignment to other parts of the system. To have an idea, here are some examples of using a single linear rail.

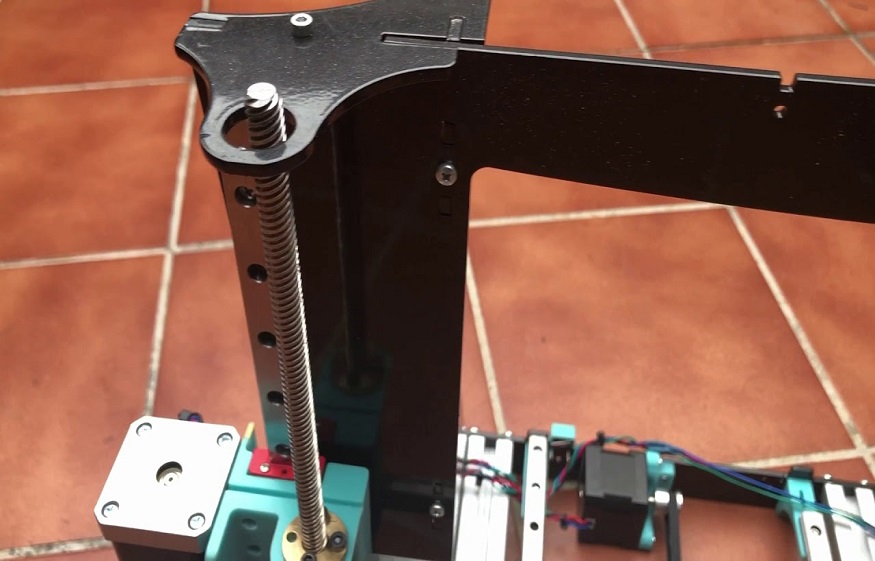

Linear actuators

It is mostly used to guide it when they are using screws, belts, or pneumatic cylinders. As they can handle any heavy loads. It can also speed up travel by 5m per second which is necessary for pneumatic driven systems or belts.

Overhead transport

Linear rails are perfect for guidance when your loads are below the rail and bearing block. It is because they can manage to transport any high load capacity and it firms the whole system.

Gantry robots

The factor of gantry has x and y axes. Every axis has a single linear rail that can be used by a bolt or screw and pulley system. When it is being used in the same direction it can have good results whether every axis uses one linear rail.

The dual rail

The linear rails can be used when there is a high moment of loads. It is allowed to load to fix the issues on the bearing blocks. In this form, the drive tool can be linked together with the linear rails which build the entire system. There are also other dual linear rail applications that are included.

Linear stages

This type of stage needs to be accurate. It needs to have less diversion and have an exact high trip. Whether the load is in the middle that has no movement. The dual linear rails are mostly used to make sure that everything is secured.

Machine tools

It is the same as in stages, the machine tools need to have a high level of travel accuracy and firmness. This is to make sure every tool creates high quality. When they use two rails in the same direction it will lessen any drift. The machine tools are prone to have high loads. It can result in four bearing blocks that help to extend its life.